What are the knowledge introductions of Syringe Plug Mold?

Having the function of safety injector plug, this mould is suitable for making self-destruction safe injection syringe. It has convenient processing and reasonable structural design.

This mould can be divided into female mould and male mould. Female mould has cylindrical cavity. The upper end of the plug has a hole and an accommodation hole. The lower end is connected with the supporting leg. There is a gap between the die and the supporting leg. This gap is convenient for cooling by technicians in the field.

The mould has an inlay on the mold base. It is made of stainless steel. The inner wall has internal threads matched with the external threads.

The

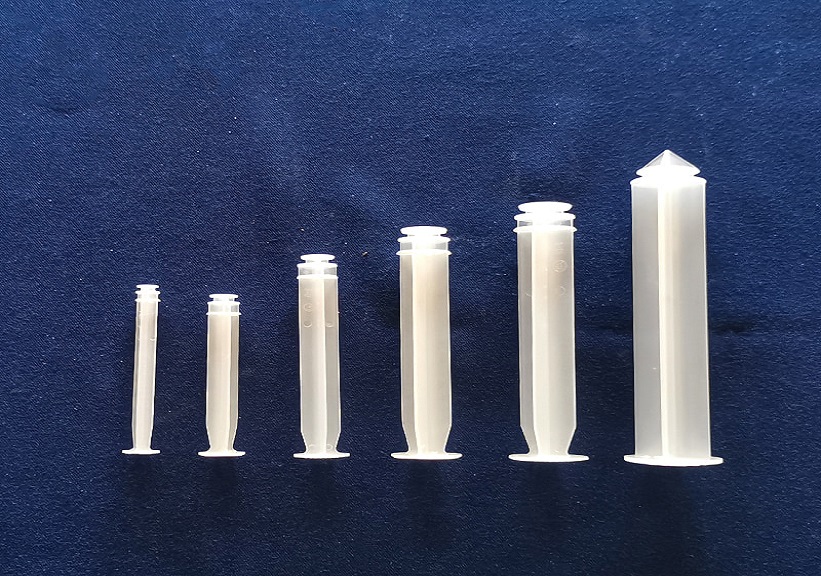

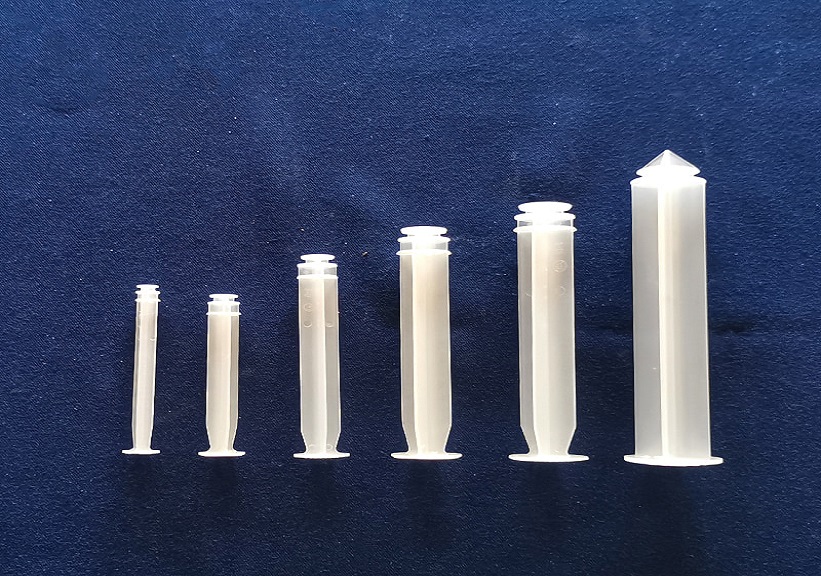

syringe plunger mould uses the well-known hot runner technology. This mould can produce rubber plugs of different specifications. Its service life is more than four million times. The mould uses high-quality materials. It can be designed for 0.5ml to 50/60ml. It has a high level of standardisation. It can be used worldwide.

This mould has a curved lever in the center. The part of the curved lever is inserted into the cylindrical shell. The inserted bar has six surfaces and has external threads. The inserted bar has a polishing treatment. This treatment can reduce the friction force between the die cavity and the inserted bar. This treatment is advantageous for drawing patterns smoothly.

The nozzle body of this mould has eight parts. Two vertical rows of four parts are arranged on both sides of the rectangular nozzle body. They are angled by 60 deg. at the side wall of the cylinder.