How to restore the deformed syringe mold?

Fracture of the syringe mold: The forged mold material itself has cracked due to improper temperature control. In this case, only the template can be replaced. Cracks and even broken templates in production are often caused by the heat treatment hardness of the selected materials being too high and the stress being too large. Cracking is easy to occur during welding, and in severe cases, it is easy to crack especially when welding Cr12 hard materials. The stress of the template is too large, and most of the impact cracks are at the sharp corners of the cavity. If it can still be used, it can be perforated and cut in an I-shaped inlay, or it can be hugged around the template. Wear of syringe molds: especially the wear of thermosetting plastic molds and aluminum alloy injection molds is serious. Insufficient hardness of the movable parts in the injection mold, sharp angles, and improper material selection are also causes of wear. For highly corrosive products and plastics with considerable hardness and fillers, the surface of the material we choose should be resistant to corrosion and have high surface hardness. Poor heat dissipation of the syringe mold: The heat dissipation of the long core mold is very important, and the selection of appropriate materials has a large gap between the appearance of the product and the output of the product. For example, materials such as beryllium copper containing beryllium and cobalt are selected, which have high strength, hardness, fatigue resistance, wear resistance and good heat transfer after heat treatment.

How to restore the syringe mold after it is deformed: During the production process of the syringe mold and the product, various defects and deformations often appear in the mold material: One of the reasons for the deformation of the material is that in order to reduce the cost, the material of the actual mold is not a special mold steel. Insufficient rigidity, insufficient thickness, improper heat treatment and residual stress, EDM stress, etc., the above reasons often interact, increasing the amount of deformation. In addition to the corresponding solutions during processing, widen the die feet or use afterburner columns to stand at each point in the middle of the die. Some molds themselves are not very demanding, and can be heated and deformed at a high temperature at the focus position, which is quite effective. People often grind off the edge of the template to reduce the contact surface, and try to reduce the grinding depth to facilitate the effective life of the mold. The deviation of the angular dimension of the cavity after the template is deformed is difficult to correct. The too tight core causes the cavity to be deformed by the wall. This phenomenon is particularly serious when there are multiple cavities. If it is used reluctantly, the flash in the middle of the template will not change. , especially for injection nylon and other products with good fluidity, the redistribution core should be smoothed. When the mold is trimmed, it is welded on a thinner seat, and the amount of deformation cannot be ignored.

What are the material requirements for syringe molds: Syringe molds are the most commonly used methods in plastic processing. This method is suitable for all thermoplastics and some thermosetting plastics. The number of plastic products produced is beyond the reach of other molding methods. As one of the main tools for the processing of syringe molds, the injection pen mold has excellent quality accuracy, manufacturing cycle and injection molding. The level of production efficiency in the process directly affects the quality, output, cost and product renewal of the product, and also determines the company's responsiveness and speed in market competition. Syringe mold requirements for materials With the development of the plastics industry, the complexity and precision of plastic products are getting higher and higher, and higher requirements are also placed on the syringe mold materials. For the manufacture of complex, precise and corrosion-resistant plastic molds, pre-hardened steels (such as PMS), corrosion-resistant steels (such as PCR) and low carbon maraging steels can be used, all of which have good machining, heat treatment and polishing. performance and high strength.

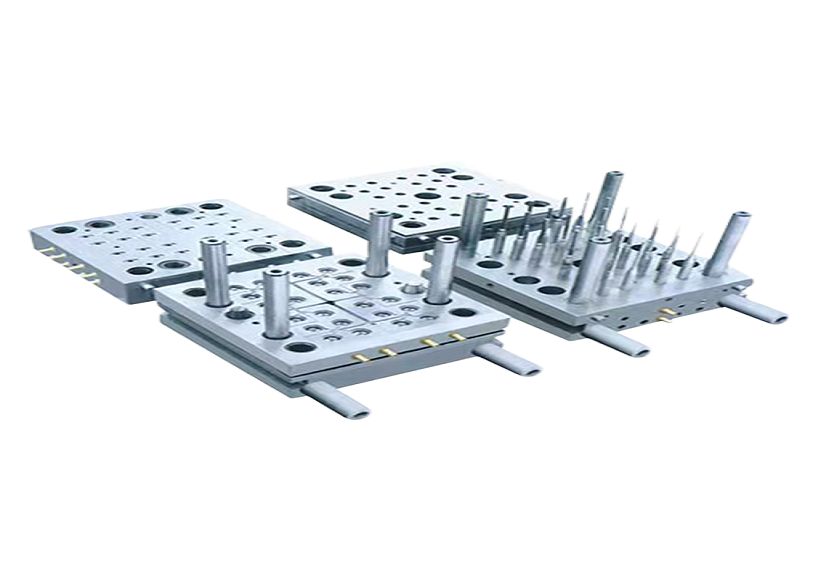

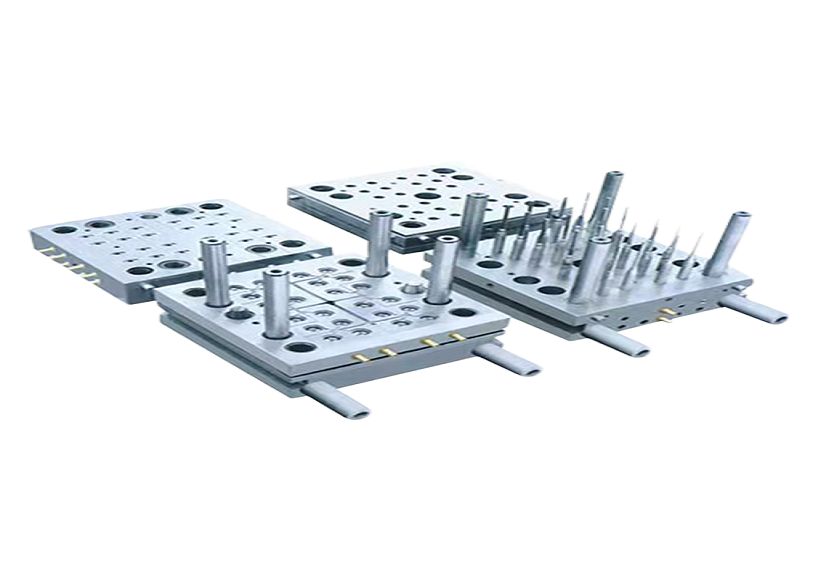

1ml insulin syringe mould

1ml insulin syringe mould