What is a plastic injection (plastic) mold?

Plastic injection (plastic) mold is mainly a molding mold that is widely used in the production of thermoplastic parts. The processing equipment corresponding to the plastic injection mold is a plastic injection molding machine. The plastic is first heated and melted in the heating barrel at the bottom of the injection machine. Then, driven by the screw or plunger of the injection machine, it enters the mold cavity through the injection machine nozzle and the pouring system of the mold, and the plastic is cooled and hardened to form, and the product is obtained by demolding. Its structure usually consists of forming parts, pouring system, guiding parts, pushing mechanism, temperature regulation system, exhaust system, supporting parts and other parts.

The manufacturing materials usually use plastic mold steel modules, and the commonly used materials are mainly carbon structural steel, carbon tool steel, alloy tool steel, high-speed steel, etc. The injection molding process is usually only suitable for the production of thermoplastic products. The plastic products produced by the injection molding process are very wide, ranging from daily necessities to various complex machinery, electrical appliances, and vehicle parts. It is the most widely used processing method in the production of plastic products.

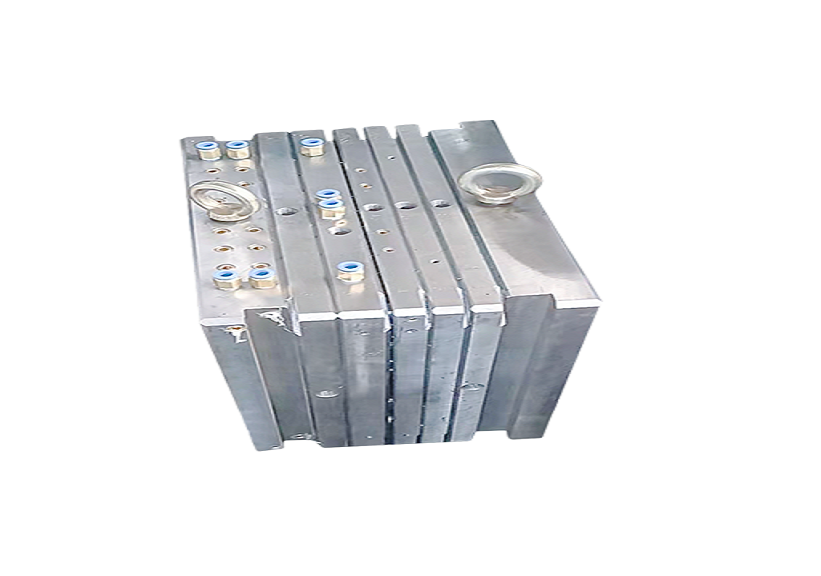

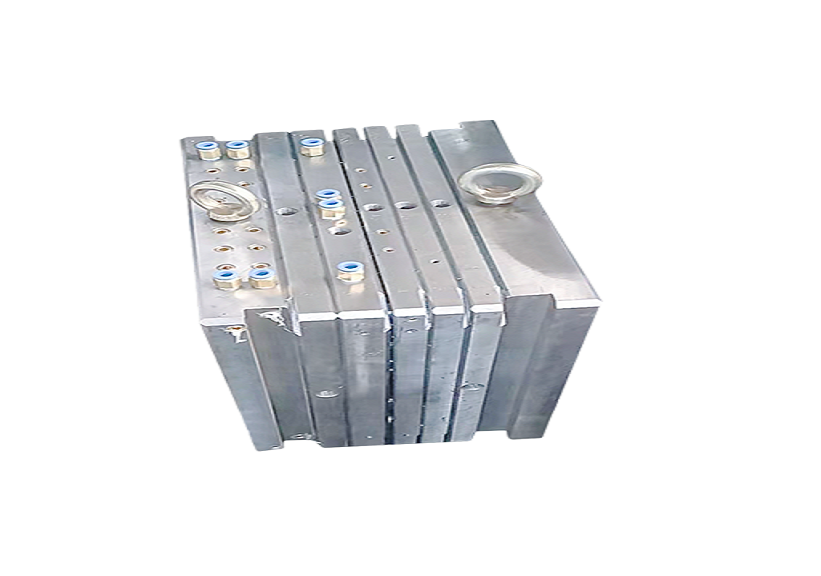

5ml syringe stopper mould

5ml syringe stopper mould