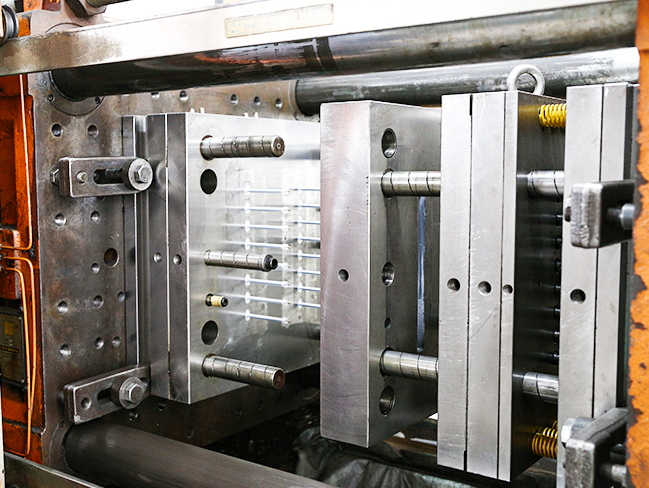

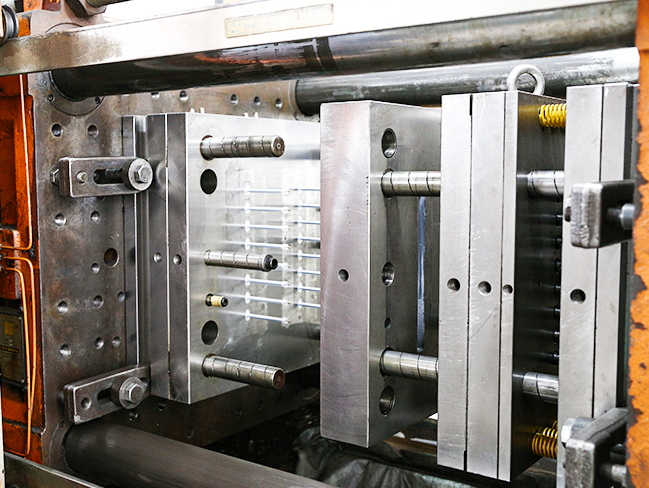

Things to consider when designing precision medical molds!

The market prospect of precision

medical molds is broad. Wenling Sanxing Medical plastic mold factory will tell you what to consider when designing precision medical molds:

1: The shape and dimensional accuracy of the target molded product, the flow direction of the resin, the transmission of the injection pressure, and the solidification of the filled resin. As a mold designer, it is necessary to know the requirements of the product, which is also the source of precision medical mold design. Therefore, the requirements of the product must be well-informed.

2: The characteristics of the object molded product should have a systematic list of the characteristics of the molded product, mainly in terms of materials, the shape of the molded product, and some details on the mold design below will be based.

3: The structure of the mold. The structure of the precision mold is different from that of the ordinary mold. There may be several possible structural design schemes for ordinary plastic molds, but for precision molds, some structures may have certain influences, so some structural schemes for precision medical molds may be very demanding. It is mainly to consider the influence of the mold action on the product.

4: The rigidity and strength of the mold. Personal experience believes that the rigidity of the mold is very important. I often see that the mold base and inner mold material of some molds are very thin. I can only say that maybe his mold can be produced, but the problem of some products is related to the strength of the mold. There is a very close relationship that is sometimes difficult to spot.

5: The glue inlet and the horizontal glue channel are important factors to control the product. The precision mold has certain requirements for the glue feeding method of the product. Making the glue point beautiful will have an unimaginable effect on the product.

6: The mold temperature control circuit, the mold should be controlled at a uniform temperature. It is necessary to set the temperature difference required in the resin flow direction, and countermeasures are required for the portion where the thickness of the meat changes. When the molded product is released from the mold, the mold surface temperature of the product part should be uniform. This requires the mold cooling system to be reasonable.

7: The precision of the precision mold is very high, and the processing method used to process the mold is very important. Dividing the mold cavity of the product according to the shape of the molded product is very common. Therefore, the processing method should be considered when designing.

8: The mold structure should be reasonable to facilitate the addition of other solutions. For example, a position may be unsatisfactory. If it is really unsatisfactory after the mold trial, a post-fill plan should be adopted.