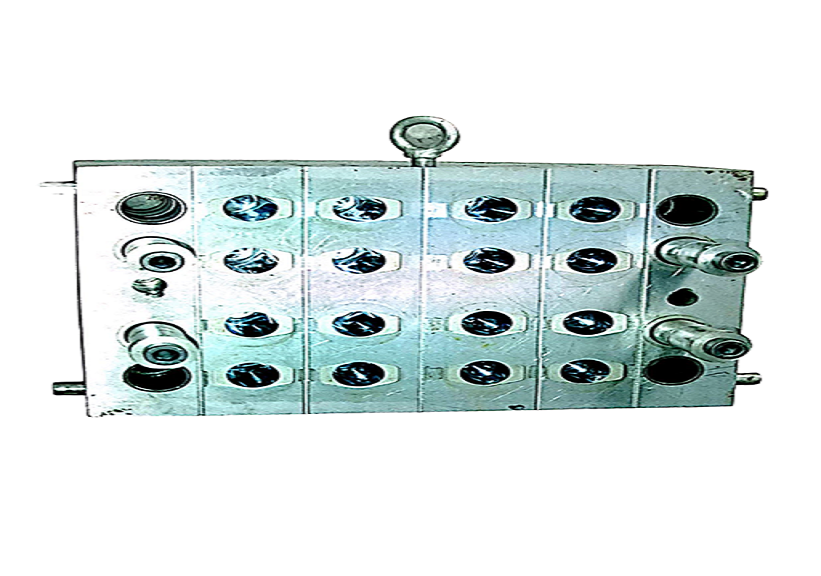

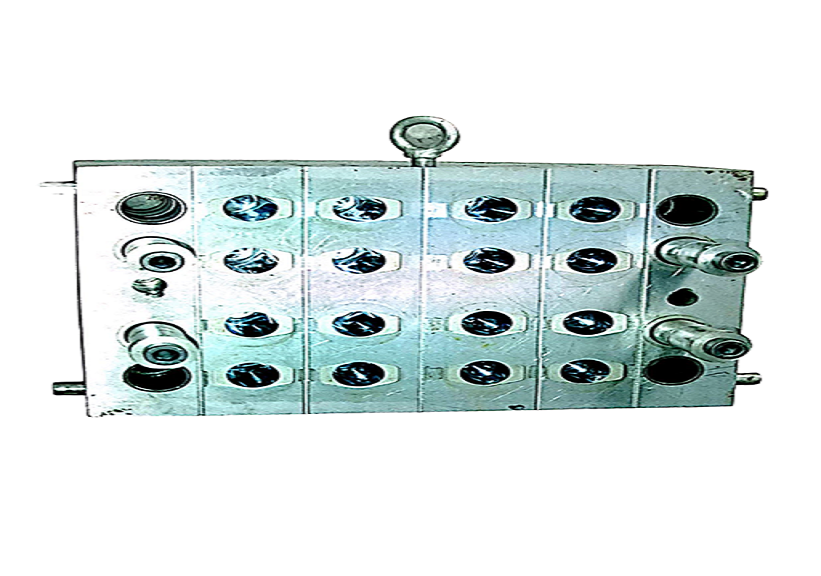

What are the Advantages of Hot Runner Mold?

Hot runner moulds are a common type of injection mold, which is used to produce products using the plastic injection molding process. They are a cost-effective and efficient way to make molded parts, and they can be used in many industries, including automotive, medical, aerospace, consumer electronics, and many more.

Advantages of hot

runner mould:

One of the advantages of hot runner molds is that they allow for increased flow, which leads to an improved cycle time and lower production costs. This allows manufacturers to reduce part weight, increase the number of cavities, and create higher quality molded parts.

Moreover, the ability to produce high volumes and quick turnaround times means that this type of mold is ideal for a variety of applications. It also enables automation of the entire injection molding process, which helps to reduce labor costs and improve efficiency.

Design flexibility:

Another major advantage of hot runner molds is their design flexibility. They allow for a wide variety of gate placement options, such as hot tip gating, edge gating, or valve gating, which can lead to better part aesthetics and optimum filling in mold cavities during the injection.

Temperature control:

The temperature of the plastic that is injected into a hot runner mold system should be controlled. This is essential to preventing issues such as under-filled parts, sink marks, and poor quality gate results. It can also help to achieve a more balanced melt flow, which helps to maintain dimensional quality and interchangeable cavities.